Powder Injection Moulding

Powder Injection Moulding – A revolution in precision metal and ceramic components production

Powder Injection Moulding (PIM), comprising Metal Injection Moulding (MIM) and Ceramic Injection Moulding (CIM), is an advanced manufacturing technology for the production of complex, high volume net-shape components.

Applicable Materials:

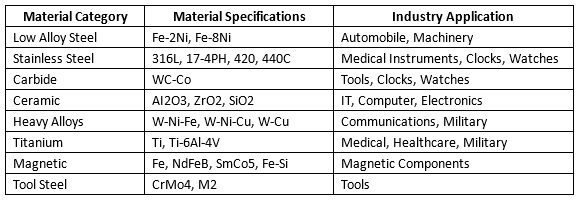

PIM is applicable to wide range of materials which includes low alloy steel, stainless steel, tool steel, nickel-based alloys, tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy and fine ceramics, etc.

Table – Typical PIM materials and applications

Advantages of MIM:

Complex geometries

Efficient use of material

Less material waste as a result of producing near net shape components and considered a green technology

Repeatability

Excellent mechanical properties

Tailored solutions using unique materials formulated to meet component/application requirements

MPP materials can be brazed/joined to a variety of components for complete assembly solutions

Complex geometries

Efficient use of material

Less material waste as a result of producing near net shape components and considered a green technology

Repeatability

Excellent mechanical properties

Tailored solutions using unique materials formulated to meet component/application requirements

MPP materials can be brazed/joined to a variety of components for complete assembly solutions